Soil water monitoring assists the producer in determining if the soil water content is between the soil’s field capacity and wilting point. Field capacity is the upper limit of water moisture that a soil can hold after it has been fully saturated and allowed to drain freely. This occurs when the water in the macropores has drained and has been replaced by air [6]. As plants use water and as water evaporates from the soil surface, the soil water content decreases. When the soil water content reaches the wilting point, plants can no longer pull water from the soil. Water contents near or below the wilting point will result in reduced yields. Saturated soils or soils with a water content above field capacity can also reduce yields. Sensors that assess the amount of water available help the producer determine when irrigation is needed and if the right amount of water is being applied. Sensors help the producer understand how many days the soil is at or below the wilting point or above field capacity. Soil water measurements can be made using either water content methods (quantity) or water potential (energy) methods.

Water Content Measurement

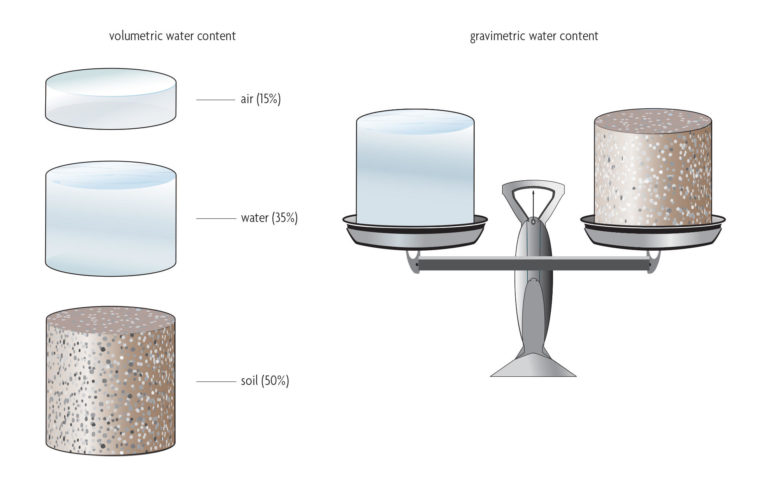

Water content can be measured by either weight (gravimetric) or volume (volumetric). Gravimetric measurement only accounts for the water and soil, while volumetric measurement also accounts for the air (Figure 14.3). Gravimetric sampling typically involves collecting and drying soil samples. Volumetric water content can be measured in the field using various sensors.

Water content measurement methods can be either direct or indirect. There are advantages and disadvantages to both approaches (Table 14.2). Direct methods are destructive, meaning that a soil sample is collected in the field and transported to a testing facility on or off farm. It takes time to process these samples, and either gravimetric or volumetric water content can be measured. An advantage of direct measurement is that it gives the exact amount of water in the soil and can be used to calibrate indirect measurement devices.

Indirect methods are nondestructive, meaning that the soil profile is not disrupted. The measurements are taken in situ, and these measurements are available instantaneously. Data from indirect measurements can be recorded and stored in specified time intervals for further analysis if needed. Since the indirect measurements are nondestructive, these measurements rely on soil properties. For indirect methods, the sensors need to be calibrated. Indirect measurements of the soil water use one of three different soil properties: its dielectric constant, its radioactivity or its thermal properties. Measurement utilizing the soil’s dielectric properties is discussed here because it is the most common.

Capacitance sensors are one of the most common indirect, in situ methods to measure volumetric water content. These types of sensors are based on the principle that soil can insulate or carry an electrical charge. The soil’s ability to do this is related to its dielectric constant. Water has a dielectric constant that is more than 10 times greater than other soil components (Table 14.3). As the soil water content increases, the dielectric value of the soil profile changes significantly. Capacitance sensors utilize this characteristic to make measurements of soil water content.

Water Potential Measurement

Soil water measurements can also be based on the pressure or suction that exists within the soil. This suction contributes to the water potential energy within the soil, which can in turn be used to predict water content. Pressure-based sensors include tensiometers, gypsum block sensors and granular matrix sensors. They utilize material that comes into equilibrium with the suction in the soil.

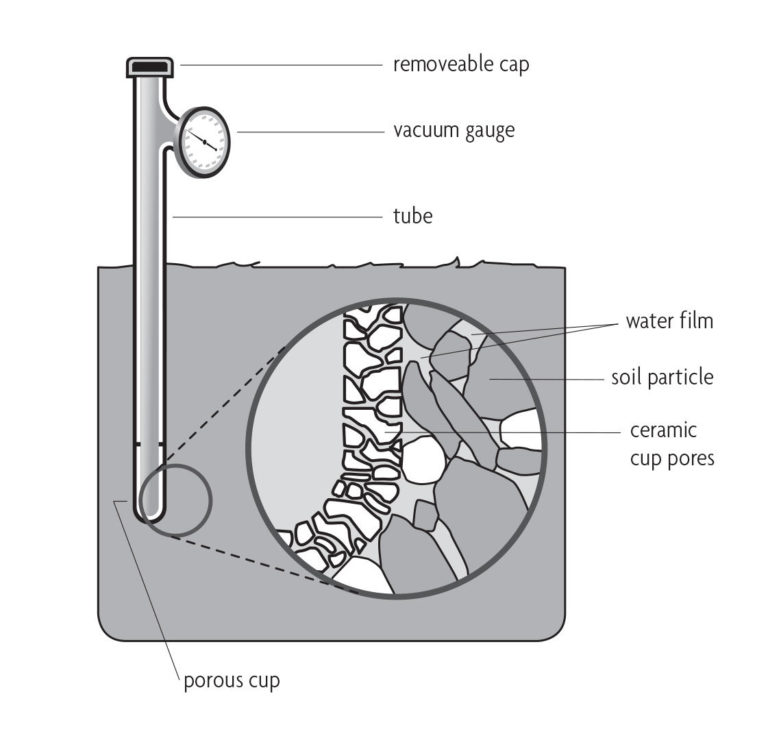

The tensiometer works on the principle that as soil water content decreases, the amount of force required by the plant root to extract soil water increases. This is mimicked in the tensiometer by filling a cylinder, with an attached ceramic cup, with water. The ceramic cup is inserted into the soil at the depth of interest. As the soil dries, the water in the tensiometer is drawn into the soil profile. This movement of water into the soil profile causes a negative pressure or suction on the cylinder of water and the negative pressure is recorded on a vacuum gauge attached to the top of the tensiometer. The reading on the gauge is an indication of the amount of water in the soil (Figure 14.4).

Both gypsum block and the granular matrix block sensors use the principle of electrical resistance to measure or indicate water content. As the soil water content increases, the block gets wet and the resistance across two wire leads embedded in the block decreases, indicating a wetter soil. The reverse is also true. The amount of soil water is determined based on a calibration of the blocks. For granular matrix blocks, ceramic is used instead of gypsum. These types of sensors are relatively inexpensive and data readers are available for each type. The reader is calibrated so the resistance measured can be translated to soil water content. One disadvantage of the gypsum blocks is that in acid soils, the gypsum can dissolve, making the blocks ineffective for long-term use. The granular matrix blocks can be used in various soil types for longer periods of time.

Managing Sensors

The number of sensors, where to locate them and the type of sensor are determined based on field conditions and producer preference. The number of sensors needed in a field will be based on the cost of sensors, the number of soil types, variations in slope, whether there are wet or dry areas, and whether variable rate irrigation is used. If a field has two different soil types, for example an area with a sandy soil and an area with a more clayey soil, a sensor or sensors are placed in each area. With a variable rate irrigation system, the amount of water applied and number of irrigation events is determined for each area.

The type of sensor to use is affected by whether the sensors are installed by the producer or a consultant. For producer-installed sensors, the water content or water potential sensors described above can be used and the desired type of output data specified. Consultants most likely have a preferred sensor type or company they use. The producer is provided with the data needed to make irrigation decisions.

When sensors are used in row-crop production, they are normally installed after planting and removed before harvest. If the soil water content is of interest when cover crops are grown, the sensors are installed after planting and removed prior to harvest or termination. The installation method and tools required vary based on the type of sensor or sensor sets. Gypsum or granular matrix sensors can be installed with a small diameter tube driven into the soil to the desired depth. The sensor is inserted into the tube. Likewise, if you use a capacitance sensor set that is in a tube, then a small diameter tube, like a soil sampling tube, is driven into the soil to produce a hole than can be used for installing the sensor. For a capacitance sensor that has to be inserted into the soil, a small hole is dug to the desired depth and the sensor is inserted into the soil profile.

There are companies that have the ability to network sensors so that all information is transmitted to a single point on the edge of a field for easy data access. Other companies have a data link to cellular systems that will send data to an electronic device, or the data is made available on a company website that is accessible whenever and wherever needed.

Overall, the number and location of sensors will depend on the field, cost and sensor product. Some consultants have started using sensors as part of their practice, so ask if they use sensors to help manage the farm.