Cover crop termination influences soil temperature, soil moisture, tillage, cash crop planting and weed suppression. It also affects the amount of nitrogen fixed by legumes or scavenged by grass as well as subsequent nitrogen release through cover crop decomposition and nitrogen uptake by the cash crop. In addition to the following information, Balkcom [2] published a management guideline to further assist growers in the Southeast in cover crop termination decisions to enhance crop productivity.

Timing of Cover Crop Termination

Due to complex interactions, the decision on termination timing must be site and situation specific, and should consider a number of factors [2]. A general rule is to terminate winter cover crops two to four weeks prior to the anticipated cash crop planting date. Table 5.5 summarizes the general effects expected following early termination or late termination.

The effects shown in Table 5.5 assume that the cover crop is suited to the climatic conditions and that the growing season is sufficient to produce adequate biomass. As a general rule, the minimum level of biomass needed to provide a good return on the investment of growing a cover crop is 4,000 pounds per acre, but lesser amounts can reduce erosion rates. Cover crop termination dates are often dictated by the target date for planting the subsequent cash crop. For example, early-planted corn (February through March) significantly shortens the cover crop growing season and eliminates the option of late termination. Consider planting the cash crop last on cover-cropped fields or using a shorter-season hybrid.

Terminating a cover crop two to four weeks before cash crop planting allows residues to dry out and become “brittle.” This enables planting equipment to easily cut through the residue. When cover crops are first terminated, the fresh, wet residue is harder to cut and can result in considerable dragging of residue by implements. In some cases, residue can become trapped in the seed furrow, a condition known as “hairpinning.” This reduces seed-soil contact, resulting in poor seed germination. Allelopathic compounds are a bigger problem with hairpinning because they are much more concentrated in the seed-placement zone, especially for crops with small seeds like cotton. Allowing a two- to four-week period between terminating cover crops and planting cash crops enables the allelochemicals to dissipate before the cash crop is established.

A recent innovation by farmers in some parts of the United States includes “planting green,” or seeding the cash crop into a living cover crop. A non-selective herbicide is used following planting but before the cash crop emerges to kill the cover crop. One advantage to planting green into a cereal rye cover crop is that the rye is still erect, which can reduce the potential for hairpinning. However, competition for soil moisture between the cover crop and emerging cash crop limits the feasibility of this practice across sandy soils of the Southeast.

Termination Method

Termination methods for cover crops can be chemical or mechanical, or a combination of the two. There are advantages to both approaches, and they are summarized here. In-depth information on terminating and planting into cover crops is in Chapter 9.

Chemical

Terminating cover crops with a non-selective herbicide is common because herbicides can be applied at any time or growth stage. In addition, most spray equipment allows coverage of a large number of acres in a short time to facilitate timely field operations. However, high-residue cover crops may lodge in many directions after chemical termination. This can negatively affect subsequent tillage or planter operations.

Mechanical

Mechanical roller/crimpers lay residues uniformly on the soil surface, parallel to the direction of planting. The residue forms a dense mat that aids in early-season weed control. Field operations (i.e., subsoiling and planting) are typically easier when residues are laid flat parallel to the direction of planting. Standing cover crop residue is more susceptible to wrapping around coulters, shanks or disks, which hinders field operations.

Roller/crimpers consist of a round drum with blunt blades mounted across the face of the drum. The traditional style consists of evenly spaced blades, but the spiral has become increasingly common because it produces less vibration. Several types of roller/crimpers have been developed, and many growers have modified existing designs to fit their situations. Roller/crimpers can be front mounted or rear mounted on tractors. Front-mounted roller/crimpers enable another implement such as the planter or sprayer to be mounted behind the tractor, which saves a trip across the field.

The roller/crimper kills the cover crop by breaking the stems, causing crop desiccation. The timing of the roller/crimper operation is critical if a grower is relying on it to terminate the cover crop. Delay using the roller/crimper until the cover crop is flowering or later, or it may not be successful. Consider this option especially if herbicides are not used in conjunction with a roller/crimper (e.g., organic growers).

Blunt blades are preferable to sharp blades because they crimp rather than cut the cover crop. Cutting or chopping results in the biomass being separated into two parts. The loose part can become oriented across the rolling direction and can cause hairpinning. If the material is crimped then it tends to lay flat in the direction of rolling, which reduces the tendency for plant material to wrap around the planter disks and shanks. When tall grasses are chopped, the lower portion of the plant may become erect in a short period of time and the benefits of rolling are lost.

Early roller/crimper designs had limitations primarily related to the speed and width of operation. Evenly spaced straight blades around the roller drum create vibration that is transferred to the tractor (and tractor operator), which dictates slower speeds. Curved or spiral blades on the roller/crimper drum enable the roller/crimper to stay in constant contact with the ground, thus allowing faster speeds and reduced vibration. Ideally, roller width should match planter width to avoid residues wrapping around coulters and disks on the planter. Due to design challenges with weight and transportation between fields, roller/crimpers are usually eight rows or smaller. Inventive growers have designed wider roller/crimpers that can be folded for transportation. Some pull-type rollers negate the need for a large tractor with a high-capacity, three-point hitch.

Integrating a roller/crimper with the planter allows producers to plant directly into a standing green cover crop. Charles Martin of Loysville, Penn., developed a roller attachment unit that is mounted directly in front of no-till planter units. The attachment is being manufactured and marketed by Dawn Biologic as the ZRX Electro-Hydraulic Roller-Crimper-Row Cleaner. The design allows farmers to delay planting to get more growth out of a cover crop. The cover crop needs to be tall enough for the roller/crimper to be effective. Crimped and flattened cover crops can be chemically terminated a few days after planting, and farmers indicate they use less herbicide on the crimped and flattened cover crop. However, potential limitations previously mentioned for sandy soils should be noted. See tables 9.1 and 9.2 in Chapter 9 for a comparison of costs and effectiveness when terminating cover crops using a roller/crimper in combination with reduced herbicide application rates.

Another mechanical option for cover crop termination is mowing after the flowering stage. Flail mowers are preferred over rotary mowers because the residues are evenly distributed and are more uniform in length. Mowing terminates the crop quickly, but it is energy intensive and there is a possibility for regrowth depending on the species and time of termination. In the humid Southeast, mowed residues break down more rapidly, negating some of the benefits of keeping the soil surface covered. Chopping residue into small pieces adversely affects the performance of tillage and planting equipment. Coulters designed to cut through residue instead push small pieces of residue into the soil and then drag the residue through the soil.

Biomass Production

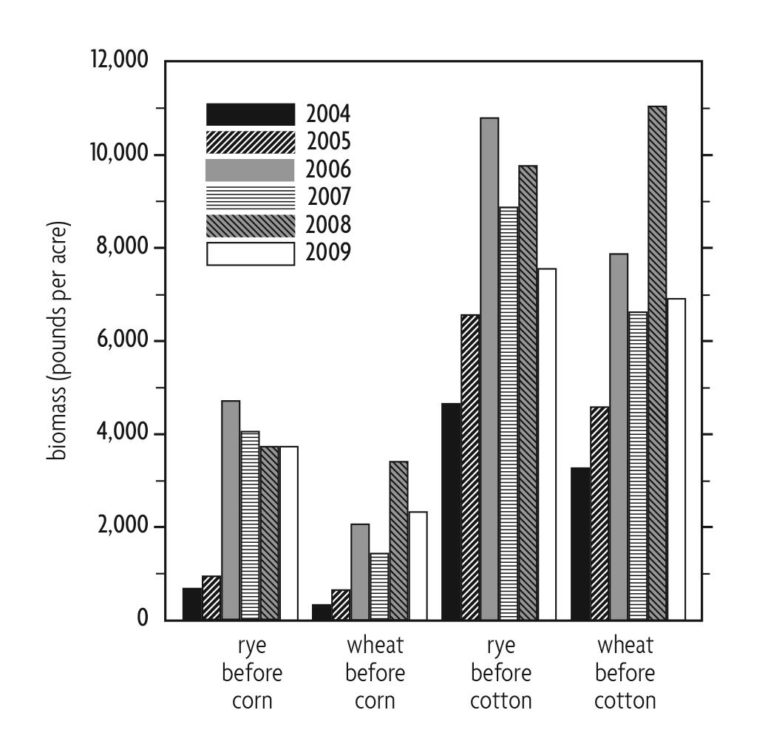

Time of termination significantly influences the amount of biomass produced. As expected, early termination reduces biomass production, while late termination promotes more biomass production. The planting date of the following cash crop dictates the termination time and also affects the biomass produced. Different cover crops produce different levels of biomass. See the dry matter information in Table 5.3.

Figure 5.3 shows differences in biomass production for rye and wheat preceding corn and cotton over five growing seasons in Prattville, Ala. Cover crops preceding corn need to be terminated about one month before those preceding cotton. The figure shows that biomass production preceding corn is always less than that preceding cotton and also shows that rye typically outperforms wheat. The inherent variability in biomass production across growing seasons is also apparent and is similar to the variability in cash crop yields.

C:N Ratio—Persistence of Residue

The carbon-to-nitrogen ratio (C:N ratio) of the cover crop at termination influences whether nitrogen will be immobilized or released. In general, mineralization or release of nitrogen occurs when the C:N ratio is below 20:1, while immobilization or sequestering of nitrogen usually occurs when the C:N ratio is above 25:1. Cover crop residues with very high C:N ratios may also immobilize some soil or fertilizer nitrogen.

The C:N ratio of small-grain residues is dependent on its maturity. Early termination of grass cover crops results in a smaller amount of residue with a low C:N ratio typical of young plant tissue. This results in rapid decomposition and limited ground coverage. Killing small-grain cover crops after flowering results in significantly more biomass and a C:N ratio usually exceeding 30:1. Such residue will usually result in an initial, if not persistent, immobilization of nitrogen during the cash crop growing season. The nitrogen content of small-grain residues varies greatly but generally ranges 20–50 pounds per acre for the aboveground biomass and 8–20 pounds per acre for the root mass. Synchronizing the release of nitrogen from residues with the period of maximum cash crop uptake can be difficult. The nitrogen contribution to the following crop from small grains depends on nitrogen availability during cover crop growth, the total biomass produced, and the growth stage and C:N ratio at termination.

The C:N ratio of mature legume residues varies 9:1–25:l and is typically well below 20:1. The lower C:N ratio of legumes allows for rapid release of nitrogen but limits the persistence of their residues. Regardless of the C:N ratio of residues, surface residues decompose more slowly than incorporated residues.