Traditional Brazilian-type rolling/crimping equipment consists of a steel drum with attached crimping bars equally spaced on the drum’s surface (Figure 9.2). This has not been widely adopted in the United States because vibration from the crimper bars is transferred to the tractor and the operator. New types of rollers/crimpers have been developed that generate less vibration. The spiral roller/crimper (Figure 9.3a) does not generate adequate force to kill the plant, so supplemental herbicide application is necessary. Newer designs have a smooth roller to flatten the cover crop and a separate bar that crimps the cover crop at regular intervals, moving up and down as the roller goes forward (Figure 9.3b).

Some roller/crimpers have been designed specifically for raised-bed vegetable production. Figure 9.4a shows 8-foot wide equipment that simultaneously terminates cover crops on two row tops and three furrows. Figure 9.4b shows equipment that simultaneously terminates one row top and two furrows.

Figure 9.4c shows a 6-foot-wide two-stage roller/crimper designed to operate with smaller tractors (40 horsepower). Note this roller is not for raised beds. The 12-inch-diameter smooth drum flattens the cover crop and the 6-inch-diameter drum has six equally spaced, quarter-inch thick crimping bars on its surface. By adjusting the springs on either side of the small drum, the crimping force can be tailored to the cover crop and amount of biomass.

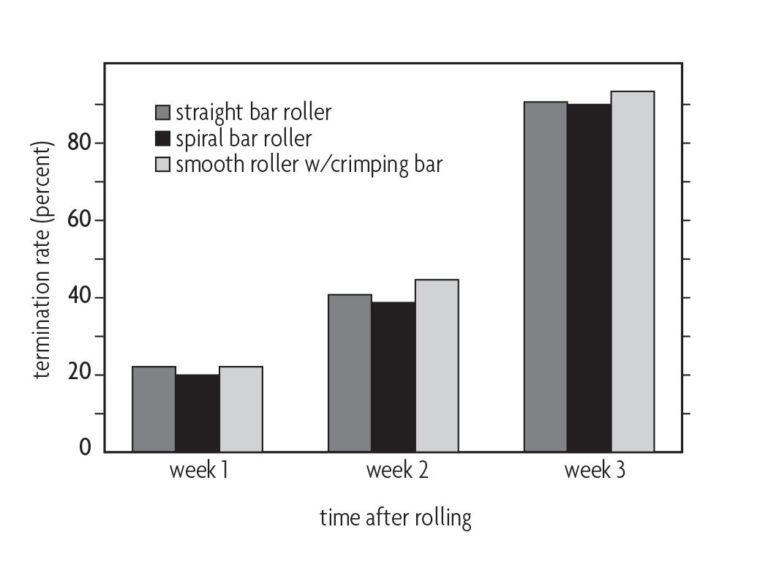

The two-stage roller/crimper has proven to be as effective as the original straight-bar roller. The percentage of the rye killed with the two-stage roller/crimper was the same as the straight-bar roller one week after rolling/crimping and better than the straight-bar roller two and three weeks after rolling/crimping (Figure 9.5).

Rolling/Crimping and Herbicide Application

Herbicide application may be needed if rolling/crimping does not terminate the cover crop in time to avoid competition with the cash crop. This typically occurs if there is a cold, wet spring, or if cover crop planting is delayed. Glyphosate is the most commonly used herbicide. It is normally sprayed continuously over the cover crop at a rate of 32 fluid ounces per acre. When combined with rolling/crimping, the glyphosate application rate can be reduced.

Figure 9.6 shows modifications to a smooth roller with a crimping bar. A custom-made boom is installed with a high-speed solenoid valve and five flat-stream discharge nozzles. Figure 9.7 shows additional modifications that result in a brief application of herbicide every second crimp. The yellow cam mechanism (C) shows that the bar crimps eight times for each drum rotation. Four engagement bolts (B) are fastened to the cam mechanism at equal intervals 4 inches from the center of the roller's rotation. As the roller rotates, the engagement bolts also rotate. When the bolt contacts the micro-switch arm (A), the solenoid valve is opened momentarily and glyphosate is discharged through the nozzles. Equipment can be modified in a similar way to apply herbicide every fourth crimp. In this case, two engagement bolts are installed.

Combining rolling/crimping with non-continuous spraying reduces herbicide application rates. Table 9.1 shows the rye termination rate when using a roller crimper in conjunction with three glyphosate treatments: continuous spray, spraying every second crimp and spraying every fourth crimp. Using this information, Table 9.2 was developed to compare costs. Spraying every second or fourth crimp results in reduced rates of glyphosate while achieving significant termination rates and cost savings.

Important note: The reduced rates of glyphosate application are only intended for cover crops that have been rolled/crimped. For effective weed control without rolling/crimping, follow the continuous-spray application rates recommended by Cooperative Extension or your appropriate state agency.

Tips for Successful Rolling/Crimping

- Plant cover crops early so they reach the growth stage optimal for termination without herbicide. Plant winter cover crops in October and November. Plant summer cover crops early enough for them to mature and be terminated before cash crop planting.

- Allow cereal grains to grow tall before termination. Rye less than 3 feet tall will eventually spring back and interfere with cash crop planting. Allow rye to reach 4 feet tall before rolling/crimping.

- Allow tall-growing covers like sunn hemp and sorghum to reach 3–3.5 feet tall before rolling/crimping.

- Successful crimping occurs when the soil surface is firm. Firm soil also prevents the cover crop from being pushed into the soil.

- Terminate cover crops at least three weeks before cash crop planting. This will prevent competition between the cash crop and cover crop for water and nutrients.

- Roll/crimp parallel to the cash crop rows to minimize planter-residue interference and buildup of residue on the planting units. Rolling perpendicular or diagonal to the cash crop rows slows emergence and lowers yields [4].

- When glyphosate application is combined with rolling/crimping, application rates can be reduced from the recommended continuous-spray application rates. Rolling/crimping equipment can be modified to allow non-continuous application of herbicide.