Fly control

The farmer cooperators on this SARE research project were able to discontinue using a feed-based larvicide and shift to topical applications of an insecticide when needed as long as the material was managed appropriately to maintain high temperatures. Fly outbreaks, though infrequent, did occur when equipment broke down and turning schedules could not be maintained. Similar success in controlling flies with in-house composting has been reported by other researchers [7].

Ammonia volatilization and control

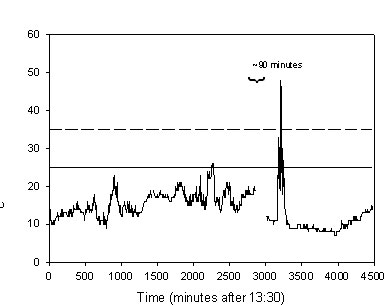

One of the main challenges with in-house composting is the accumulation of high levels of ammonia and other gasses inside layer houses and venting of these gasses from the facility. Active biological decomposition coupled with the low carbon to nitrogen ratio and frequent turning of the material contributes to higher ammonia levels than in high-rise layer facilities where manure accumulates in static beds. Monitoring showed that atmospheric ammonia in the composting area peaked well above safe levels for humans and poultry when the compost was being turned (Figure 3). Atmospheric ammonia was also higher in winter when fan use to cool buildings was reduced. Ammonia concentrations in the cage area were less than 50% of the concentrations in the composting area due to air flow patterns created by operation of the ventilation system [8].

There are several options to manage atmospheric ammonia during in-house composting. Practices that conserve nitrogen and reduce ammonia volatilization are the most desirable and environmentally sustainable solutions. Using rates of carbon calculated to maintain optimum C:N ratios will increase ammonia assimilation by microorganisms and reduce ammonia volatilization. Chemical amendments such as aluminum sulfate also have the potential to reduce ammonia volatilization from in-house compost [9], but more research remains to be done in this area. To reduce exposure in the short term, facility personnel where this research was conducted would over-ride the automated fan system for 15 to 30 minutes to vent ammonia when compost was being turned. It is recommended that facilities using in-house composting invest in ammonia gas sensors to prevent exposure of workers and poultry to high levels of atmospheric ammonia. In light of impending air quality regulations, practitioners of in-house composting also are cautioned to adopt practices that reduce ammonia emissions from poultry facilities.