The farms included in this chapter were chosen for their interesting, innovative and integrated approach to weed management. These farms are also innovative in a variety of other ways. Most notably, all achieve a substantial reduction in tillage relative to otherwise similar organic farms.

The farms include both large and small farms, and they represent both field crop and vegetable production systems. The farms span a wide geographical range.

The Martens

Penn Yan, N.Y.

Grain, forage and processing vegetables

Klaas, Mary-Howell and Peter Martens grow a wide range of grain, forage and, in some years, processing vegetable crops on 1,700 acres of certified organic land in the Finger Lakes region of central New York. The Martens are widely acknowledged as leaders in the organic farming community, and their advice is widely sought by growers in New York and beyond. Among the more notable aspects of their farm is the high level of weed control. Their son, Peter, an expert in weed management in his own right, is playing an increasing role in the management of the farm. In addition to farming, the Martens operate Lakeview Organic Grain, a feed mill and organic seed company that is at the heart of a growing organic grain and dairy industry in central New York. Another son, Daniel, is active in the management of the mill and seed business.

Consistently good weed management is difficult to achieve on a large organic farm in the humid Northeast, where rain in early summer often interferes with timely cultivation. Although cultivation is a key element in the Martens’ weed management, other elements of their farming system complement the cultivation and help keep their fields clean. These include a diverse crop mix, sound crop rotation, cover cropping, timing of field operations and careful nutrient management.

The Martens grow a wide variety of crops including food grade soybeans, dry beans, corn, spelt, wheat, triticale, barley, oats and, depending on market conditions, cabbage, snap beans and sweet corn. Recently, they began growing perennial and annual forages for neighboring dairy farms. They regularly experiment with new crops like hull-less oats and edamame soybeans. Their clean fields and careful management allow them to sell much of the harvest as certified seed to other growers through their seed company. The high diversity of crops they grow spreads out the workload, making timely cultivation more feasible. In addition, the wide range of crops provides a variety of opportunities for disrupting weed life cycles. For example, the cabbage is sufficiently high value that they can justify hiring a crew to hoe it, and this provides a level of weed control that is rare on a farm growing only grain crops.

For many years, their basic crop rotation was soybeans, then a small grain overseeded with red clover, followed by a heavy feeding row crop like corn or cabbage. They sometimes departed from this sequence due to weather, market demands and other considerations, but it provided a framework for planning their assignment of crops to fields each year. This rotation helped control weeds. The alternation of winter grains with spring sown row crops helps control both spring and fall germinating weeds. By the time spring germinating weeds begin to establish, the winter grains are growing vigorously and competitively suppress these weeds. The Martens usually overseed the winter grains with red clover while the ground is still frozen. The clover thus establishes early and competes with weeds as the grain begins to dry down and becomes less competitive. After the grain is harvested, they wait until the weeds begin to flower and then mow the weeds and clover at 4–6 inches. By waiting until the weeds start to mature, they reduce the weeds' ability to sprout from below the mowing height while ensuring a high vigor in the clover. Consequently, few weeds produce seeds during a year with winter grain.

By the time the clover is plowed under for planting corn or another heavy feeding crop, it has had a full year to fix nitrogen. As a result, the Martens only need a little organic fertilizer in the seed box to get high corn yields. The soybeans usually do not receive fertilizer, but based on results of a Cornell University organic cropping systems experiment (Caldwell 2016), they have been applying manure before planting winter grains.

The disruption of life cycles created by high crop diversity and crop rotation, coupled with minimal use of soluble fertilizers, has prevented any one weed species from becoming a severe problem on the farm. In 2002 and 2003 several scientists, including the authors, studied most aspects of the Martens’ operation, including the weeds in their fields. A list of the three most abundant weeds in each of five key crops (soybeans, corn, spelt, cabbage and snap beans) included 15 species, an unusually diverse community for a farm. Common lambsquarters, quackgrass, ragweed and giant foxtail were among the most commonly encountered species, yet none of these weeds were very productive. Weed dry weight in the field crops rarely exceeded 300 pounds per acre and was often much less, though a few fields had moderately high weed dry weight in the 500–1,200 pounds per acre range. Weeds in the vegetables never exceeded 100 pounds per acre and were usually less than 10 pounds per acre.

In recent years, the Martens developed innovative cooperative agreements with three small dairy farms in the neighborhood. In this arrangement, the Martens supply all of the forage, grain concentrate and bedding needed by the dairy farms in exchange for a percentage of the milk check. The arrangement gives the Martens an incentive to provide the highest quality feed for the cows and ensures high productivity of the organic dairy herds. The addition of forage crops to the farm has further increased crop diversity and provided new crop rotation opportunities. For example, black turtle beans can be grown after triticale harvested for forage, and brown mid-rib (BMR) sorghum-sudangrass can be grown after a winter barley crop. Double cropping forages with grains not only increases the profitability of the farm, but it also provides new opportunities for interrupting weed life cycles. The Martens avoid growing corn for silage. Klaas believes that the annual forages they grow produce higher quality forage and that, by double cropping them with grains, the profitability is greater. With the increased crop diversity, they now largely avoid growing soybeans after corn, which he says sets the soil up for erosion.

As an additional consequence of the Martens’ close relationship with the neighboring dairy farms, they now raise 70 replacement heifers. Raising heifers allows them to keep three fields in a creek floodplain in permanent pasture. Rather than losing soil during flood events, they now capture soil with permanent grass sod. Any new weed species arriving in the floodwater is much less likely to establish in a grazed and trampled pasture than in an arable field. They also graze the heifers on cover crops. This allows them to incorporate the cover crops without mowing first.

Since the Martens take back the manure from the dairy barns, they are able to close the nutrient cycles on the farm in a way that was impossible when they concentrated on cash crops. The grain going to their mill and seed company slowly draws down the excess P and K from an earlier era. This reduces the vigor of many weed species relative to farms that regularly apply high rates of off-farm manure as a nitrogen source.

The great diversity of their crop mix allows them opportunities to plant a rye cover crop before soybeans. They then roll down the rye with a roller-crimper on the front of the tractor and drill the soybeans into rolled down rye in a single pass. This practice was not feasible when the soybeans followed corn since the corn was harvested too late to plant the rye. The absence of soil disturbance and the temperature-moderating effect of the rye avoids triggering weed seed germination. Their Great Plains drill has a 5-inch spacing between the openers, which leads to rapid canopy closure to suppress any weeds that break through the rye mulch. In the occasional year with a spring drought, the rye can dry out the soil enough to prevent good soybean emergence. In dry springs, they cut the rye for silage to avoid this problem.

Although the Martens use a multi-tactic approach to weed management, their innovative mechanical methods distinguish them from other growers in the Northeast. Early season in-row weed management is critical for successful weed control in field crops, and Klaas and Peter have become experts in the art of tine weeding. They believe that different situations require different machines. For soybeans and beans, which have a deep taproot, they often use a Lely, because the close spacing of the 85-degree tines allows aggressive uprooting of weeds, but the flexibility of the thin Lely tines allows them to bend around the relatively brittle beans. After dissatisfaction with the performance of the Lely and a straight tine Kovar in corn, Klaas asked the Kovar Co. to make him a weeder with a 45-degree tine. The shallower bend avoids uprooting of young corn but is more aggressive than the straight tine. The 45-degree Kovar weeder is now marketed nationally. When soil is relatively wet, the Martens shift to the straight tine Kovar. Klaas points out that uprooted weeds do not dry out when the soil is damp, so the objective then is to bury small seedlings. The straight tine more effectively throws a wake of soil than a bent tine. They also bought a set of Einboch gangs that they have adapted to mount on a Kovar frame. Multiple machines and careful set up adjustments optimize tine weeding in a variety of crops and soil conditions.

The Martens have a good farm shop with substantial capacity for fabrication. And they use it. Among their more important creations are several 6-row belly-mounted cultivators they have fabricated out of older machines. These were the mainstay of their row-crop cultivation for many years. The belly mounted machines carry two gang bars per row, with each gang pulling just a single half sweep next to the row. This configuration allows each sweep to have its own gauge wheel, so if a gauge wheel goes over a rock, only one sweep comes up out of the ground. More importantly, however, the belly mounted cultivators allow the Martens to cultivate close to young crops early in the season. Such exact cultivation would be impossible with a rear-mounted cultivator alone. To rip out weeds in the inter-row area, however, they do pull a three-point hitch mounted cultivator with heavy C-shanks. Klaas prefers C-shanks to S-shanks because he says weeds can slip between the shovels on the more flexible S-shanks.

Although a lot of the Martens’ soybeans are now no-till planted into rolled down rye, they still cultivate many row crops. After poor satisfaction with RTK GPS guidance for cultivation, they purchased a machine vision system for a 6-row rear mounted cultivator. The machine vision system has two cameras that focus on different rows. Klaas says that this arrangement prevents a single camera from becoming confused by shadows, weedy patches and thin places in a row. The high accuracy of the machine vision system allows Klaas and Peter to run Kress rubber star wheels in the crop row. Klaas says that this often allows them to skip the final tine weeding. Although they still use the belly mounted cultivators, Klaas says that the machine vision system allows them to cultivate four times faster and requires less skill to operate.

Although they do not currently use RTK GPS when cultivating, they find it very useful for planting accurately. Much of their planting is done with a 240 horsepower, GPS guided Fendt tractor. They have fitted an in-line disk and power harrow with three-point hitches, which carry either their Great Plains drill or Case IH planter units, depending on the crop being planted. To balance the weight, they feed the drill or planter from Amazone air-seeder boxes on the front of the tractor. The tractor is sufficiently heavy and powerful to pick up both the tillage implement and drill or planter. This system allows them to till and plant in a single pass. Although the tractor is heavy, they reduce potential compaction using dual rear wheels and lowering the tire pressure to 13 pounds per square inch. More critically, their single pass tillage and planting system avoids the compaction associated with driving over tilled ground for secondary tillage and planting. GPS guidance during planting allows precise placement of successive passes, which facilitates subsequent good cultivation of the guess rows. GPS guidance also allows precise planting along strip edges. Before they had the GPS guidance, the strip edges tended to become weedy because the edge row would get off into the adjacent strip. That problem has now been solved. But Klaas warns that the tradeoff for the accuracy of GPS and machine vision is the considerable effort of programming computers and maintaining the effectiveness of sensors.

In the rare event that an unacceptable number of weeds survive cultivation and break through the canopy of a soybean or bean crop, the Martens use a homemade "weed-topper" to cut off the flowering stalks before they can set seed. This tool consists of a hydraulically adjustable front-mounted toolbar equipped with rotary mower blades. Each blade is driven by a separate hydraulic motor, and alternation of shorter and longer shafts allows overlap of adjacent blades. The weed topper reduces competition with the crop, debris in the harvested beans and the number of weeds that have to be managed in the succeeding crops.

A critical component in the Martens’ weed management program is vigorous crops. They maintain and adjust their planters to get solid stands without skips. This denies weeds gaps where they could proliferate. They also usually delay corn planting until the second half of May. This allows more time for clover to grow. In addition, the warm soil of late spring reduces seed rot of their untreated organic seed and promotes quick emergence and fast early growth. This allows a good head start on the weeds and maximizes the effectiveness of their mechanical management.

The Martens’ feed mill and seed business, Lakeview Organic Grain, is a key part of their farm operation. It provides a market for the wide range of crops they produce, thereby contributing to the high diversity of their cropping system. As an independent business, Lakeview now dwarfs the farm in sales and its grain purchases provide a stable market for organic grain growers across New York State. Lakeview ships the feed it produces in bulk throughout most of New York and much of Pennsylvania, and they ship palleted bag feed throughout the Northeast. The seed wing of the business provides growers with an extensive range of certified organic and untreated conventional grain, forage and cover crop seed. They also sell animal health care products. The Martens feel they have a mission to foster organic agriculture in their region. As a consequence, they try hard to maintain relatively stable prices both for their customers and for the farmers they buy from.

Through a variety of good farm management practices, coupled with careful attention to the details of cultivation, the Martens achieve a level of weed control that makes their advice sought after by farmers across the continent. Their enthusiasm for organic farming and generosity of spirit leads them to answer dozens of questions a week from farmers and agricultural professionals. The Lakeview newsletter includes not just the usual company price list but also provides many pages of useful information about feeding practices, animal health, the agronomy of various crops and the results of the many experiments they conduct on their farm. They invite people to call and ask questions. Working while talking on a cell phone has become a way of life. They were also the guiding force behind the creation of New York Certified Organic (NYCO), a large group of growers that meets three times each winter to hear guest speakers and discuss a wide range of farming issues. When a grower is facing a particularly difficult problem, one of the Martens frequently has a helpful suggestion.

Paul Mugge

Sutherland, Iowa

Soybeans, corn and small grains

Paul Mugge grows 300 acres of certified organic soybeans, corn and small grains in northwest Iowa. After decades following low-spray practices and relying largely on organic fertility sources, he decided to take the farm organic in the late 1990s. His first acreage was certified in 2000, and the whole farm has been certified since 2002. When he decided to get out of pork production in 2007, he expanded his acreage from the 300-acre home farm and began organically custom cropping an additional 500 acres owned by a local egg producer. Mugge discontinued operating that farm a few years later to concentrate on his home farm.

Mugge rotates tillage practices as well as crops. He believes that changing between spring and fall planted crops and between row- and solid-seeded crops helps him suppress weeds. His basic crop rotation is corn-soybeans-small grain-corn. The corn and soybeans are planted on 30-inch centers, which allows effective inter-row cultivation, and the fall planted cereals suppress spring germinating weeds. The small grain slot in the rotation is often fall sown triticale or wheat. He also grows spring wheat, oats and barley. He overseeds 12–14 pounds per acre of medium red clover onto his winter grains with a spinner as early as possible in the spring. He tries to broadcast the clover while the ground is still frozen, but as often as not the weather takes his fields directly from snow to mud. He says that even sowing later when the ground is drying consistently produces a good stand. The spring grains are also seeded with clover. For the spring crops, he puts the clover in the grass seed box of his John Deere drill and plants the grain and clover in a single pass.

Although his crop rotation is not unusual among organic grain growers in the northern half of the United States, the tillage methods Mugge uses within this rotation are highly innovative. He had trouble killing the red clover varieties available in Iowa in the spring before corn planting without a moldboard plow. So, he began planting a southern clover variety, “Cherokee,” which he later replaced with “Southern Belle,” a variety that has better seed availability. These southern clover varieties weaken during the cold Iowa winters. With the clover winter damaged, he found he could incorporate it with just a disk and field cultivator.

The backbone of Mugge’s tillage rotation, however, is ridge-tillage planting of soybeans. He begins the year before by building ridges in the corn with the hilling disks on his Buffalo single sweep cultivator. This not only buries weeds in the corn row but also provides a 6-inch ridge for the following year. He added spacers to the front and rear wheels on his combine so that the wheels travel in the valleys between ridges. The 26-inch-wide tires on the combine nip the edges of the ridges a bit, but for the most part the ridges are well preserved. Mugge believes that ridge-tillage has reduced grass weeds on his farm.

The fall grain is no-till drilled immediately following the soybean harvest. The no-till drill is adjusted so that the height of the leading coulters matches the height of the ridges left behind from cultivating the soybeans. In this way the seeding depth of the grain is uniform across the width of the drill, and the ridges and residue cover are maintained. The grain is overseeded in the spring with the red clover. Corn follows the small grain. The clover is incorporated with disks and a field cultivator, which prepares a seedbed for corn. This tillage rotation has allowed Mugge to move completely away from high-draft chisel and moldboard plowing. He finds the ridge tillage soybean system particularly beneficial. "Ridge till saves a lot of fuel and a lot of time, and it’s good for soil conservation,” Mugge says. “On the contours it's like a mini-terrace every 30 inches.”

All Mugge’s implements are 30 feet wide, with the planters and row crop cultivators set up for 12 rows on 30-inch spacing. In addition to his Buffalo planter and cultivator, he has a White planter that he uses for corn and an International cultivator set up with three shanks per row. He has a Yetter rotary hoe with staggered, self-cleaning wheel arrangement that allows it to be used in high residue conditions. He also has an Einbock tine weeder that he uses primarily in corn.

Mugge usually uses his Einbock tine weeder two to three times in corn, both before and after emergence. If the soil crusts, he uses the rotary hoe instead of the tine weeder. His first inter-row cultivation is with the International, which throws some soil off the front sweeps into the row to bury small weed seedlings. At the second and last cultivation, he switches to the Buffalo to really hill up around the corn to bury even some larger weeds and create the ridge for next year’s soybeans. Mugge has found that staggering the disk hillers on the Buffalo by 2 feet really improves weed control in the row. The forward disk knocks the seedlings over, and then the rear disk covers them up.

In the soybeans, Mugge rotary hoes once and, if possible, twice before emergence at three- to four-day intervals. Then after the soybeans are up, he rotary hoes again. In contrast with the corn, his first two cultivations in the soybeans are with the Buffalo cultivator because it is better able to handle the heavy corn residue that is in the inter-row areas. To make the corn residue easier to handle, he has installed Calmer stalk rolls on the combine corn head that chop up the stalks. At the final cultivation, the residue has broken down, and he uses the International because it can cultivate closer to the crop row. Mugge uses RTK GPS guidance to steer the tractor between the crop rows. He also has cultivating mirrors on both sides of his tractor that allow him to see the position of the cultivator well enough that he can cultivate within one inch of the crop row. If the cultivator drifts out of optimal position, he manually overrides the GPS guidance to re-center the sweeps on the row. Mugge warns, however, that if the wind is from behind, dust raised by the cultivator can obscure the mirrors.

Mugge has a flame weeder that he uses on both corn and soybeans if some extra weed control is needed. He flames the soybeans at the cotyledon stage. The soybeans get a little singed but recover. He flames the corn when it is 18–30" tall. By this stage, the leaves are above the flames and the stalks resist the heat. This treatment kills many of the weeds that escaped cultivation and reduces both competition with the corn and production of weed seeds that could infest subsequent crops. He says that flame weeding has a lot of potential, but learning to do it well is difficult.

Mugge does not tine weed or rotary hoe his small grain crops because that would disturb the clover. Annual weeds rarely get a chance to go to seed in his grain fields, however, because weeds that bounce back after combining get mowed again in August. The rapid regrowth of the clover suppresses them after that.

Mugge teaches physics and advanced mathematics courses part-time at the local high school. “This keeps my mind active,” he says. Teaching also lets him get to know a lot of high school students, some of whom he hires in the summer to pull weeds in his soybeans. “Back before herbicides, most farmers used to walk their beans, but people have gotten away from that now.” Mugge’s soybeans are all high protein, food grade beans. Keeping the fields free of weeds reduces staining of the beans during harvest and allows him to sell a premium product to highly discriminating customers. The hand weeding also leads to very low weed seed production during the soybean phase of the crop rotation. This leads to a small weed seed bank on the soil surface, which makes a successful no-till planted grain possible.

Mugge’s training as an engineer and his interest in science led him to regularly experiment with new farming practices. He has been participating in on-farm trials with Practical Farmers of Iowa for more than 25 years. These experiments are frequently well-designed trials that are suitable for the statistical analyses he teaches his students. In 2010 he collaborated with Iowa State University plant breeders on a trial of an aphid resistant soybean variety. “It wasn’t a bad year for aphids, so it wasn’t a good test,” Mugge says, “but the new variety hardly had any aphids, whereas the strain without the aphid resistant genes had around 100 per plant.” All his soybeans now have the two-gene resistance trait, and much of his crop is sold as seed to other growers.

The increase in extreme weather events in recent years has been a challenge for farmers across the country, and Iowan farmers have suffered more than most. Mugge has been more fortunate than some with flood prone land. But he notes that the 5 inches of rain that he got in early October 2019 made harvesting high-quality soybeans for seed difficult. No farmer can make the weather cooperate with his plans, but Mugge’s innovative methods and continuing willingness to tinker with his systems increase the resiliency of his operation.

Eric and Anne Nordell

Beech Grove Farm

Trout Run, Penn.

Fresh market vegetables and herbs

Eric and Anne Nordell summarize their weed management philosophy as “weed the soil, not the crop.” When they bought their 90-acre farm in the rolling hills of northern Pennsylvania in 1982, they made several decisions: They would farm with horses; they would farm organically; and they would avoid hiring laborers. They quickly realized that avoiding hired labor meant that they needed to get the weeds under control at the outset and keep them under control permanently. Otherwise, they would either work themselves to exhaustion or have to hire in help.

Since the ground where they planned to grow vegetables had been in hay for many years, the field was thick with quackgrass and other perennials. So, they planted high value herbs in a half-acre field and fallowed the six-acre area where they planned to grow vegetables. Plowing followed by repeated harrowing exhausted and dried out the quackgrass rhizomes while flushing out and killing a lot of annual weed seeds. To compensate for a potential decline in soil quality due to the fallowing, and to smother out remaining quackgrass, they planted a thick cover crop of rye early that fall.

The success of the fallowing/cover crop treatment led to development of a weed suppressive crop rotation scheme in which cash crops alternate with years of cover crops and fallow. "Instead of relying on the cultivator or the hoe to save the crop from the weeds,” they say, “we use cultural practices, including cover cropping, bare fallow periods, rotation and shallow tillage to reduce the overall weed pressure in the soil" (Nordell and Nordell 2007). This approach to weed management has reduced weed pressure on the farm to extraordinarily low levels. One of the authors crawled down 40 feet of un-hoed lettuce about ready for harvest in 2003 and only found a single common chickweed and one volunteer rye plant, each about 2 inches tall. The weeds are so well controlled that the Nordells now commonly plant onions without tillage, a practice that would be unthinkable on most vegetable farms.

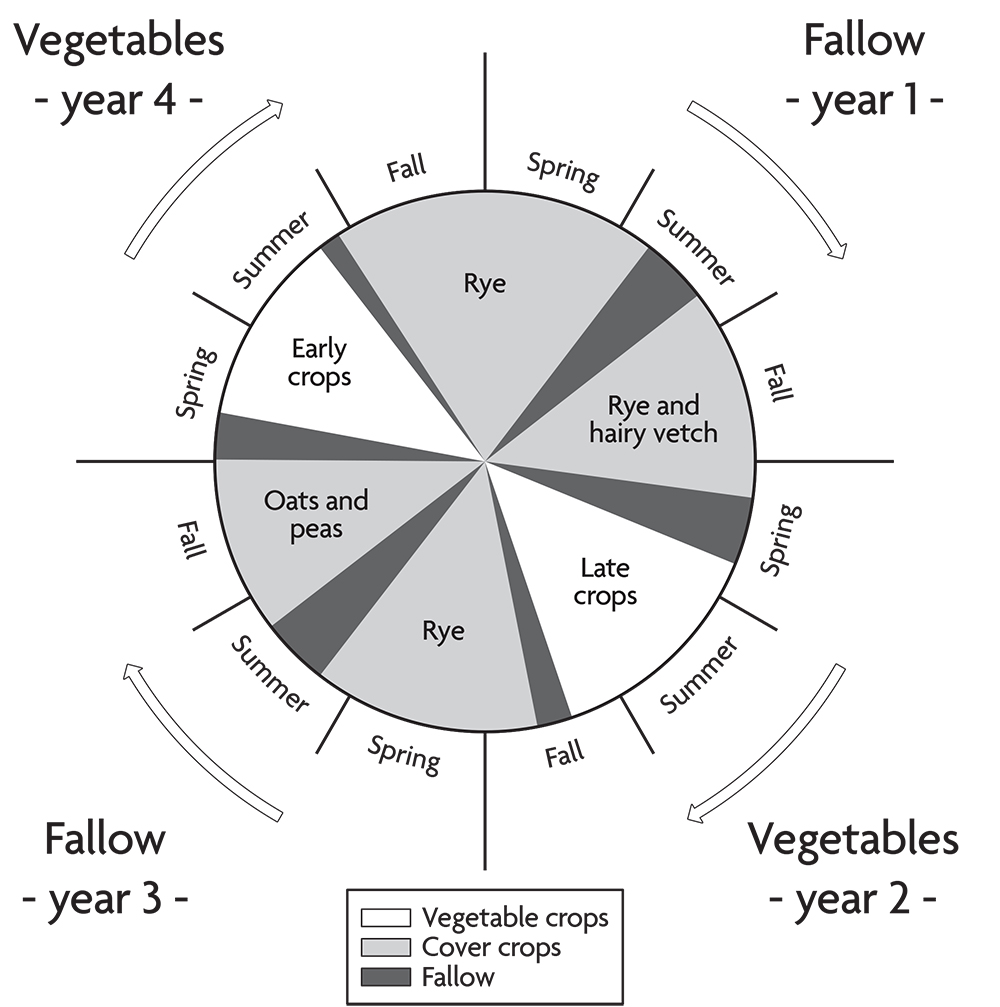

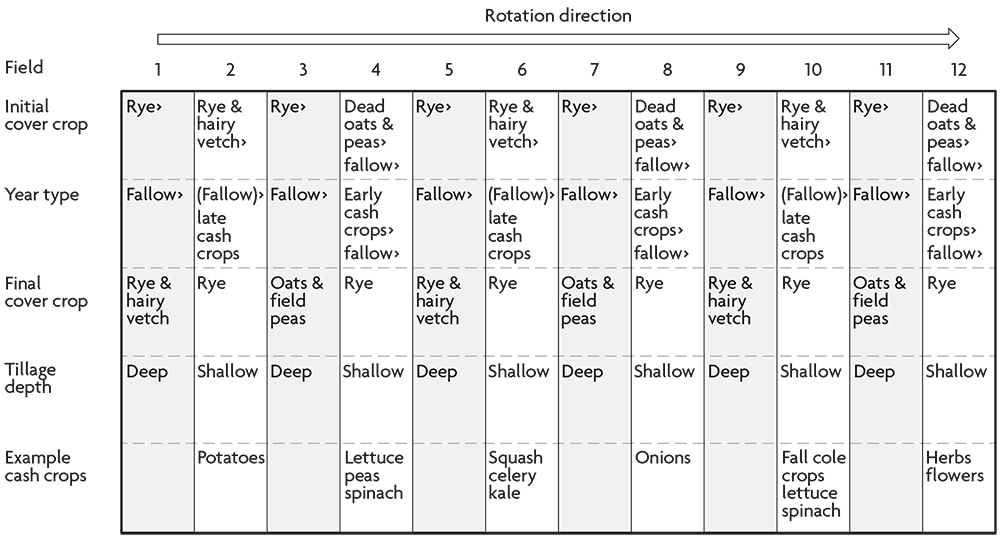

The key to their weed management program is alternating cash crops with bare fallows and weed suppressive cover crops in a regular but flexible four-year crop rotation (Figure 5.1). They have divided their vegetable field into 12 half-acre strips. Thus, in any given year, they plant each of the four sets of crop categories in the rotation in three field sections (Figure 5.2). Each year, the crop categories move to the right in Figure 5.2 by one section. The rotation is deliberate and systematic, but it is also highly flexible. They can adjust the species and amount of various crops within any of the three early sections to respond to weather conditions and market opportunities. Similarly, they can adjust the late crops as necessary.

Following a bare fallow in the summer of year one, they plant a rye/hairy vetch cover crop. The absence of a cash crop in year 1 allows them to plant the vetch in mid-August for optimum growth before winter. Good growth in the fall means that they can mow and plow under the rye/hairy vetch cover crop early in year two and still build soil structure. For early summer crops, they incorporate the cover crop in April and use some compost for supplementary nitrogen. For later planted crops they incorporate the cover crops in May after the vetch has fixed substantial nitrogen. Although the surface soil is inverted with a moldboard plow, when incorporating the rye and vetch in early spring, they disturb only about the top 3 inches, an operation they call “skim plowing.” They use disks to incorporate the heavier cover crop biomass in late spring. They then fallow the field for about six weeks before planting their late planted crops. This fallow period provides an opportunity to flush out cool-season-germinating weeds like common chickweed. A wide range of crops can go into the late crop slot, from squash or a summer planting of lettuce to fall harvested broccoli. After the late crops are harvested, they till shallowly and plant rye. If they plan to harvest the crop late in the fall, they interplant a row of rye between the crop rows after the last cultivation. This does not compete with the crop but tillers and eventually sprawls out to provide good soil cover over the winter.

Year three of the rotation is devoted to fallow and cover crops. The Nordells mow the rye two to three times in the spring before it begins to head. This promotes rapid regrowth and prolongs the growth of the rye well into June. In late June or early July, they moldboard plow in the rye. They then shallowly till with a spring tooth harrow if the residue is light or with a field cultivator if the residue is heavy, at about 10- to 14-day intervals until the time comes to plant the fall cover crop. In the first year the Nordells farmed the field, they maintained the fallow for three months. As the weeds declined, they have reduced the summer fallow period to as little as three weeks. When they were still fighting quackgrass, they used a spring tooth harrow to work the rhizomes to the surface and shake the soil free from the roots. In later years they have often pulled a cultipacker behind the spring tooth harrow or field cultivator. This combination produces a firm seedbed that promotes germination of weed seeds so they can be eliminated with the next cultivation. After the fallow period, the farm broadcasts and works in oats and field peas in early August. If done poorly, broadcast seeding can produce a patchy stand. In the hands of the Nordells, however, broadcast seeding produces a more uniformly spaced stand than drilling could, and consequently the cover crop canopy quickly closes to smother late emerging weeds. Increasingly they now create ridges with disk hillers after broadcasting the oats and peas, in preparation for ridge planted crops the next year. The oats and peas produce a dense, lush growth before being killed by frost in late fall.

They grow early planted crops in year 4 of the rotation. These include peas, spinach and early lettuce but especially onions, which are one of the farm’s specialties. If the field section was ridged the year before, they scrape off the tops of the ridges to create narrow bands of bare soil for planting. The raised ridge warms quickly and promotes rapid early growth for the early planted crops. They disk lightly field sections that are planted “on the flat” to break up the oat and pea residue, and they then undercut any weeds with broad, widely spaced sweeps on a field cultivator. This shallow tillage avoids bringing up weed seeds into the surface zone that was cleaned by the fallowing the previous year. They follow the early planted crops with rye or a mixture of rye and spelt. The winter grain cover crop is mowed two or three times the following spring (the beginning of year one of the rotation). They eventually incorporate the cover crop by plowing and then begin the fallow period.

The Nordells adjust both the length and timing of the fallow as necessary to arrest potential weed problems before they develop. If weeds are increasing, they will lengthen the fallow period. In contrast, if weeds are virtually absent from a strip, the fallow will be short and cover crops will be left on the field for more of the season. They shift the fallow period from summer to spring if cool season annuals appear to be increasing.

Although the Nordells cultivate both early and late planted vegetables, they emphasize that this is largely to conserve soil moisture. The cultivation creates a shallow “dust mulch” that interrupts capillary flow of water to the soil surface. Also, they usually stop cultivating two to six weeks after planting to interseed a single row of rye or hairy vetch between the rows. Often, no cultivation for weed control would be needed to achieve high yields.

Eliminating any weeds that do emerge is important, however, to prevent seed production. If necessary, the Nordells hand rogue out any weeds that threaten to produce seeds. The weeds are so well controlled by other means that the time required for hand weeding is minimal, but the Nordells are very consistent in preventing weeds from going to seed. Their system depends on this consistency. The fallow periods eliminate a large percentage of the surface seed bank. If many seeds were allowed to enter the soil during vegetable years, their weed problems following the fallow year, though reduced, would still require much cultivation and hoeing in later crops.

Note that the Nordells do not use a nitrogen fixing cover crop like hairy vetch before the long summer fallow periods (Figure 5.1). No crops are present during the fallow to take up the nitrogen. In addition to creating potential environmental problems, excess nitrogen would tend to promote weeds. Instead, they strategically position the nitrogen fixing cover crops prior to the vegetable crops that can use the nitrogen. By supplying most of their crops’ nitrogen requirements with legume cover crops, the Nordells avoid the need for large amounts of compost. Low compost rates have prevented the build up of excessive levels of phosphorus and potassium that would promote weeds like purslane and hairy galinsoga. Research at Cornell has shown that the Nordells’ farming system maintains a balance between inputs and exports of N, P and K.

The Nordells’ whole-farm approach to weed control has led to an elegantly integrated management system. The economics of the farm operation is supported by careful attention to the biological life of the farm. For example, the four-year rotation sequence (Figures 5.3 and 5.4) makes long lags before replanting a particular crop family relatively easy. This prevents build up of soilborne diseases. The potentially destructive impact of the bare fallow periods is balanced by large and repeated inputs of soil building cover crops, and by reduced tillage during the vegetable years of the cycle. Despite the fallow periods, the Nordells’ soil scores very well on various measures of soil health (Gugino et al. 2007). Their approach to farming provides a whole new meaning to the phrase “feed and weed.”

Scott Park

Park Farming Organics

Meridian, Calif.

Tomatoes and other vegetables, vegetable seed, rice and other grain crops

Scott Park grows 900 acres of vegetables and 800 acres of grain in the Central Valley of California near Sacramento. He has been farming since 1973 and farming organically since 1986. In that time, he has developed an integrated but flexible strategy for dealing with weeds. “Weeds are my major battle,” he says. “They are 10 times more of a problem than nutrients, water management and other production issues.”

With an operation his size, Park needs a lot of help. He has his son, Brian, and 15 full-time employees. “Everybody knows how to do all the different tasks. We don’t specialize,” he says. That allows everyone to keep busy all year around. Park’s wife Ulla handles the bookkeeping, which is fully computerized. “We can track each of our 27 fields as if it were a separate enterprise,” he says. He says that the careful recordkeeping really helps with organic certification; it also helps them evaluate profitability of farm practices over multiple years.

Park approaches weed management from a long-term perspective. “A lot of crop rotation decisions are made for weed management rather than for what the net profit will be this year.” Developing crop rotations that effectively suppress weeds is facilitated by the diversity of crops produced on the farm. Processing tomatoes are his biggest money maker and typically cover about 20% of his acreage. In addition, he produces substantial acreage of lettuce, peas, dry beans and edible sunflower seed. He also typically grows more than 200 acres of vegetable crops for seed, including various cucurbits, brassicas, lettuce, herbs and others. The vegetable crops are balanced in the rotation by rice, wheat and field corn. In fields where he can grow rice, a typical rotation would be rice-dry beans or peas-winter wheat-tomatoes-rice. Flooding the rice is good at suppressing field bindweed and johnsongrass, which Park rates at the top of his “misery index” of weeds. Other major weeds on the farm include pigweeds, common lambsquarters and watergrass (barnyardgrass). Since the rice depletes nitrogen and produces a lot of residue that ties up the remaining N, Park usually follows rice with a nitrogen fixing legume crop. Wheat comes next to prepare the field for tomatoes. The wheat is harvested in June, which leaves plenty of time for a tilled fallow to flush weeds out of the soil. He will typically irrigate after wheat harvest to bring the weeds up and then tills shallowly through the summer to kill successive flushes. If the field bindweed is still bad at wheat harvest, he may even flood the field for a few weeks before beginning the fallow. In the fall, he plants a legume cover crop of purple vetch, Magnus peas or bell beans in a mixture with a small amount of wheat or other grain. The cover crop helps suppress weeds through the rainy winter months and supplies some N for the following tomato crop, though he also spreads chicken litter before planting the heavy feeding tomatoes. Some fields have too much slope for rice or are adjacent to neighboring walnut orchards that cannot tolerate flooding. On these fields, a typical rotation might be wheat/cover crop–tomatoes/cover crop–vegetable–winter wheat, or corn–cover crop–tomatoes. In this sequence, winter wheat works well after a summer harvested vegetable, whereas corn works well after a fall harvested one. Although the crop sequences are typical of the sort Park uses, he emphasizes that his choice of crop depends on the weed pressure in a field. He plans ahead one to two years so that weeds will be manageable in each succeeding crop.

In addition to flooding for control of perennial weeds, the rotation sequences Park uses suppress weeds in several important ways. First, the alternation between spring, summer and fall planted crops and cover crops interrupts weed life cycles so that the same weed species rarely can prosper for two years in a row. Second, drilled rice and wheat make dense canopies, which tend to smother out weeds, whereas other species are planted in wider rows and can be cultivated. Thus, the basic weed management strategy varies from one crop in the sequence to the next, and this also helps prevent the buildup of particular species. Finally, Park tries to plan his crop sequences so that the ground stays covered except when he is using a tilled fallow to deplete the seed bank. When growing tomatoes, he aims to have the plants completely cover the beds to provide competition against weeds and protect the soil. With crops or cover crops continuously present on the fields, either desirable plants are there to compete with the weeds or a high value vegetable crop is present to provide an incentive for attacking the weeds with cultivators and hoes.

Building soil quality is a critical part of Scott’s farming practice. The farm’s silt loam and clay loam soils could become massive and difficult to work if not carefully managed. The entire farm is laid out in permanent beds on 60-inch centers. In much of the country, growing grain crops in permanent beds would seem peculiar, but most of Park’s fields are furrow irrigated, and the furrows between the beds provide a route for water to get to the crops, whether they are vegetables or grains. The furrows provide permanent drive tracks for the tractors, so that the soil in the beds is never compacted. This, coupled with high residue inputs from the grain and cover crops, gives his soil excellent aggregation. The soil has good waterholding capacity, and this really helps with weed control. “In the spring, we transplant the crop, and its roots are moist,” Park says. “But the soil surface dries out so that the weeds don’t germinate. We may not need to irrigate for 40 days. If the soil structure is bad, then you have to irrigate right away, and this brings on the weeds.” In rice production, Park pre-irrigates, then scratches the soil and drills the rice seed into moisture 2.5 inches deep. The light tillage eliminates the weeds germinated from the irrigation, plus dries out the top 2 inches to curtail further weed germination. The rice can grow 6 inches tall before permanent flood is established. Waiting to start permanent flood also provides an opportunity to scratch out some weeds that come after planting.

To manage tillage and cultivation on multiple beds at a time, Park and his staff have purchased and built a wide range of specialized equipment. First, the beds are laid out exactly with a GPS system. This means that every unit of a multi-bed machine is squarely centered on the bed. “The GPS steers the tractor,” Park says. “The tractor operator is there to turn the tractor around at the end of the field and in case something goes wrong.” Key implements include ground driven bed mulchers, furrow rippers and Lilliston rolling cultivators. Much of the tillage is shallow, and Park commonly uses row crop cultivators as tillage tools by swapping around knives and sweeps. For example, before wheat, he incorporates chicken litter with a Lilliston rolling cultivator equipped with 46-inch sweeps in addition to the spider gangs. Then he just scratches the soil surface with a Lilliston before planting. After harvest, he disks in the wheat residue. Deeper tillage with a chisel plow usually occurs on a given field only once every couple of years, usually before a high value vegetable crop.

Park Farming Organics has 20 different cultivators, many of which they built themselves. These are set up on sleds, which provide precise depth control on fields that have been leveled for furrow irrigation. They also make their own cultivating knives, which allows them to cheaply replace worn out knives. Since they sharpen their cultivating knives to cut weeds more effectively, knives need to be replaced regularly. Making their own knives also allows them to customize cultivators for any row spacing. This allows them to cultivate effectively while using the space on the beds optimally. “We have cultivators set up to cultivate one row, two rows, up to 10 rows per bed depending on the crop,” Park says. Many of the knives are made with a pipe welded to the back side. This ensures that the weeds are not just cut off below ground but are lifted so that they dry out and do not reroot. Commonly a cultivator will be set up with a standard blade in front followed by a blade with a pipe behind. Soil is sometimes deliberately thrown into the crop row to bury small weeds if the crop can tolerate it. But an advantage of the special blades is that they provide good disturbance of the weeds with little of the lateral movement of the soil that one gets with a steeper pitched sweep. This is critical when cultivating close to small vegetable plants. And they do cultivate close! “With the GPS steering the tractor, we can cultivate to within 1.5 inches of the row,” Park says.

They also have flame weeders set up for both in-row flaming of crops and flaming of beds to create stale seedbeds. “We don’t use the flame weeders a lot,” Park notes, “but they are useful for some crops and situations.” Over the years he has tried other weed control methods but found them unsuitable for his farm. “All our crops are harvested mechanically, and plastic mulch interferes with the mechanical harvesters,” he says. “It is also too much work to dispose of after harvest.” In conjunction with University of California researchers, he also experimented with natural product herbicides, including high concentration vinegar, but found these too expensive for use on a commercial scale.

In addition to precision cultivation, Park hires crews to hoe the vegetable crops. The tomatoes get hoed one to three times depending on the weed pressure. He times hoeing relative to irrigation so that the surface soil is dry. That way weeds do not germinate after the soil is moved by the hoes. The crews use conventional, long-handled, 4-inch-wide garden hoes for the work. That kind of hoe moves more soil around than he would like. “But that is the kind of hoe they prefer,” he says. “I guess it’s what they are used to.”

All of the crops are harvested mechanically, and this kills most of the weeds present at harvest. Fields are cleaned up and planted with a cover crop or another crop quickly after harvest to prevent weed regrowth and seed set. Park also takes measures to prevent weeds from setting seeds in the crop. He once burned a wheat field rather than let an infestation of canary grass go to seed. That was before his management methods had been refined, and in any case, field burning is no longer allowed. He has equipment set up so that he can drive over the tomato beds and mow off the flowering stalks of weeds that poke out above the crop. He will also do an extra hoeing to prevent weeds from setting seed if necessary.

Park believes in building strong relationships. With such a diversity of crops he needs to work with several different buyers, but he has built up a history of trust with each of them. “I have been working with most of these companies for decades,” he says. “We don’t plant unless I have some parameters on what we can get for the crop, but often the contract doesn’t get signed until after delivery. I know they will buy what they agreed to, and they know I will come through with the goods. In 46 years, I’ve only had to pay a lawyer for four hours of work.”

Whether it is marketing or weed management, avoiding problems is a big part of Park’s strategy for successful farming. “I am out in the fields every day,” he says, “and I keep my eyes open.” When he saw fiddleneck coming into one field, he had it hoed up and removed the plants from the field. He and his crew also clean machinery before moving to a different field to avoid spreading weeds from one part of the farm to another. Weeds may be Park’s major battle and perhaps one that can never be entirely won. But with this sort of care, Park Farming Organics can hold their own in the struggle and ensure that the farm continues to prosper.

Carl Pepper

O’Donnell, Texas

Cotton

Carl Pepper grows organic cotton on the High Plains of west Texas, a region that has sometimes been called “the world’s largest cotton patch.” By paying attention to the biology of his system and developing equipment specially adapted to his operation, he grows one of the world’s most chemical intensive crops without any chemicals at all. When he began farming on his own in 1992, he began experimenting with an organic approach on 160 acres. He currently grows organic cotton on 3,200 acres of his own farm and another 300 acres on his sister-in-law’s farm.

Compared with most organic farms, Pepper’s crop rotation is remarkably simple. All of his land is planted to cotton each summer and is planted with a cover crop in the fall. The usual cover crop seeding consists of 10–12 pounds per acre of a mix consisting of 70% rye, 20% tillage radish and 10% hairy vetch. Despite the minimal diversity of the rotation, he has seen no buildup of diseases, insects or weeds over the 25 plus years he has been farming this land. He attributes the low disease and insect pressure to the arid climate of west Texas. He has also noticed that if he leaves the aphids alone early in the season, they attract beneficial insects that attack more serious pests later. Often bollworm populations in his fields crash by natural processes about the same time his neighbors are spraying for this pest. Since cotton matures earlier farther south in Texas, he gets an early warning in years when bollworms are particularly bad, and, if necessary, he releases Trichogramma wasps to help suppress the pest.

Since Pepper does not irrigate, much of his attention is focused on water conservation and ensuring that soil moisture is sufficient to support his cotton. This includes preventing the growth of weeds. And on the windy plains of Texas, preventing soil erosion is similarly critical. To simultaneously conserve water, keep the soil in place and manage weeds, he has developed an integrated tillage/cultivation system that relies on machinery that he and his full-time crew of four employees designed and built themselves. The beauty of his system can be best understood by following the annual crop cycle.

The cover crop is sown into the unpicked cotton before the last cultivation in late September or early October. The low seeding rate of 10–12 pounds per acre is just sufficient in a wet winter to provide good cover, but in a dry winter, it is sparse enough to prevent the cover crop from using moisture the cotton will need later. He begins cultivating the cover crop to suppress it and kill weeds beginning in early March. For this purpose, he uses low-pitch 24-inch sweeps on 20-inch centers, with alternate sweeps centered on the future crop row and on the center of the inter-row (Figure 5.3). A high accuracy GPS system allows him to keep the tractor on the same tire tracks throughout this and all subsequent operations. The sweeps travel only 2 inches deep and undercut the cover crop while leaving it on the soil surface to protect the soil. Another one or two such operations eventually kill the cover crop while keeping weeds suppressed until planting time.

Pepper’s soils range from sandy loams to clay loams. Most have a moderate number of rocks, but in a few places the soil is shallow over bedrock. The finer textured soils have produced good cotton yields for decades with very little added fertility. On the sandier soils, Pepper used to apply 1–2 tons per acre of composted cattle manure prior to planting, but for the last several years he has found that the compost is unnecessary. The lack of fertility inputs probably helps limit weed growth. Since the harvested crop is mostly carbohydrate in the form of cotton lint, most nutrients remain in the field. Possibly due to the consistent use of cover crops and a conservation tillage system, he has seen an increase in soil organic matter of 0.3.–0.8% over the years. Since a 0.1% increase in organic matter represents one ton per acre of additional organic matter in the soil, this increase represents an important additional source of nutrients.

Pepper begins planting cotton between May 15 and June 10. He uses a plant eight, skip one row planting pattern. The skipped row provides access for ATVs during hand weeding. Pepper uses a high seeding rate because he expects his aggressive weeding later in the season will kill some plants. Thus, he plants at three seeds per foot of row, hoping for 2.25–2.5 plants per foot at harvest.

His post-planting weeding begins with a cultivator composed of rotary hoe gangs alternating with sand fighters on the same toolbar. The sand fighters are metal triangles with extensions on the sides. These are welded on an axle in a staggered fashion so that, looked at from the side, they look like a six-pointed star. The sand fighters flip divots of soil to create surface roughness that reduces wind erosion. His rotary hoe units over the crop line consist of an angle iron frame holding two offset lines of hoe arms. The front line has three arms and 1.5-inch spacers on the ends. The second line has four arms. Thus, the hoe wheels on each section are 3 inches apart, but the sections are staggered so that the overall spacing of wheels for the whole implement is 1.5 inches. He runs this implement at 10–16 mph, which covers his extensive acreage in two days. “I’d estimate we kill 90% of the annual weeds with each pass of the hoe,” Pepper says. He continues using the rotary hoe after each rain event until the cotton reaches the two- to four-leaf stage. At that point he switches to a specially modified row crop cultivator. This has low pitch 32-inch sweeps that keep the cover crop and weed residue on the soil surface to prevent wind erosion. Over the crop rows he mounts a gang of rotary hoe wheels spaced 2 inches apart to continue the in-row weeding. Perhaps the most unique feature of the cultivator, however, is the spring-steel hay baler pick-up fingers he has bolted to the wings of the sweeps. These reach out toward the crop row at a 30-degree angle to cut off or uproot weeds close to the crop row. The forward motion of the cultivator causes the springs to deflect away from the cotton, but this creates pressure toward the row, causing the soil to boil and disturb small weed seedlings. Pepper begins with the spring tips spaced about 1–1.5 inches apart and runs the cultivator at 5 mph. A GPS controlled mounting on the three-point hitch keeps the cultivator well centered on the crop rows.

Pepper cultivates after each rain to keep the soil surface loose. This prevents capillary draw of moisture from deeper in the soil. During long periods without rain, he cultivates every 30 days to keep perennial weeds suppressed. After the cotton reaches the six-leaf stage, the rotary hoe gangs are removed from the cultivators. But as the bark on the roots toughens, he is able to move the spring fingers on the sweeps ever closer to the row, until, by the end of the season, he has the fingers crossed so that the row is thoroughly cultivated. With the help of his GPS guidance system, he is able to cultivate at 8 mph by the end of the season. Although he makes many passes over the field with one sort of cultivator or another, he avoids compaction by consistently following the same wheel tracks, and the low draft of his implements results in a typical fuel use of only 0.25 gallons per acre of diesel. To successfully manage soil moisture, the machinery needs to move fast, and Pepper and his crew can cultivate the entire 3,500 acres in six to seven days.

Pepper’s major annual weeds are kochia, devil’s claw and Palmer amaranth, which in his region is called careless weed. Silverleaf nightshade, lakeweed (a spurge) and field bindweed are perennials that are problems in parts of some fields. To control the perennials, he breaks from his standard minimum tillage and plows to disrupt the root systems. He only plows, however, in the part of a field where the perennials are a problem. To ensure that the weeds do not spread, he and his crew scrape down the plow and cultivators after they are used in areas infested with perennials.

Although Pepper’s tillage/cultivation system does a good job of eliminating most weeds, he still finds some hand hoeing necessary. For fields where escapes are more plentiful, he hires in an eight-person hoeing crew. On most of the land, where the weeds are sparser, his regular full-time staff spends about two hours per acre hoeing. To clean up any escapes, they also roam through the skip rows on 4-wheel ATVs to hand rouge out escapes. He estimates that hand weeding cost an average of about $30 per acre, which he considers a good investment. The hand weeding helps conserve moisture for the cotton, and it also reduces seed production by the annuals and the buildup of root reserves in the perennials. “My fields are generally cleaner than my neighbor’s GMO cotton,” Pepper notes.

Pepper broadcasts the cover crop seed into the standing cotton near the end of September, give or take about two weeks. He then cultivates for a final time to eliminate any remaining weeds and to incorporate the cover crop seed. He times the seeding and cultivation so that moisture is adequate for establishment of the cover crop. By harvest in November, the field is green. Since Pepper does not use defoliants, he waits until a freeze kills the leaves before harvesting the cotton. The first freeze comes about November 6, on average, and he usually begins harvesting around Thanksgiving.

Pepper’s integrated system for conserving moisture, protecting the soil and managing weeds produces 300–400 pounds per acre of cotton lint, a harvest that regularly matches the county average. One of the keys to Pepper’s success is good preparation. “We spend a lot of time in the shop making sure that everything is ready to go when the time is right.” This preparation is critical since most operations are timed to rainfall events. Pepper also recognizes that his crew of four full-time employees is one of the keys to his success. “They have bought into the system,” he says. “We work really hard when something needs to be done, but when there is a slack period, they get to spend time with their families. Family comes first, but the farm feeds the family.”

Chapter 5 References

Caldwell, B., C.L. Mohler, Q.M. Ketterings and A. DiTommaso. 2014. Yields and profitability during and after transition in organic grain cropping systems. Agronomy Journal 106: 871–880.

Gugino, B.K., O.J. Idowu, R.R. Schindelbeck, H.M. van Es, D.W. Wolfe, J.E. Thies and G.S. Abawi. 2007. Cornell soil health assessment training manual edition 1.2. Cornell University, Geneva, New York.

Nordell, A. and E. Nordell. 2007. Weed the Soil, not the Crop: a Whole Farm Approach to Weed Management. Available from the authors.