Some producers cover loose cells with a 1-inch (2.54-centimeter) layer of sawdust or vermiculite during incubation. It is thought that bees and parasites can work their way through this material, but that parasitic wasps cannot return through the material to re-infest other cells. Perlite should not be used for this purpose as it contains a static charge that can adhere to the hairs on the bee’s body.

Prior to beginning incubation, black lights and water pans should be in place (Figure 7.21). These light traps consist of a water-filled tray to which a few drops of detergent are added to break the surface tension. Mounted above the tray is a black light. Parasitic insects, especially chalcid wasps, are attracted to the ultraviolet light and drown in the water. Because some parasitic insects are poor fliers, these light traps should be located on the floor of the incubation room, so that they can hop down to the light traps rather than trying to climb up to them. A single window located in the incubation room can be used instead of a black light, again with a water-filled tray placed below the window. Remember bees will also be attracted to these light traps, and screened covers should be in place on the incubation trays prior to emergence. Screened lids do not necessarily need to be in place until male bees begin to emerge, and in some instances the lids may hinder the removal of parasites from the incubator. The walls of the incubation room should also be vacuumed several times a day to remove chalcid wasps. See Appendix A for more information on controlling pest insects during incubation.

Canadian leafcutter producers have a long-standing practice of placing dichlorvos (VaponaTM) pest strips inside incubation rooms during the early stages of pupal development. These strips are then removed after several days, and the room is aerated to remove any remaining vapors. If timed correctly, the dichlorvos strips are very effective at killing parasitic chalcid wasps. When not timed correctly, not properly vented, or under high humidity conditions, dichlorvos can be extremely lethal to bees. These pest strips are not labeled for this use in the US; using them in leafcutter operations is illegal, potentially dangerous to both bee and the beekeeper alike, and their use is not recommended. Similarly some Canadian producers have recently begun fumigating nest equipment and incubating cells with high concentrations of formaldehyde gas to control chalkbrood disease. The beekeepers that do this require extensive protective equipment and chemicals to neutralize the gas during venting. This is an extremely hazardous process that has not been approved in the US. It should not be attempted.

Leafcutter Beekeeping: A Note From The Author

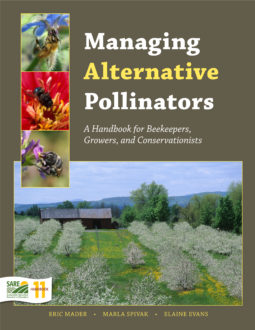

Prior to my current work as the appealing crops like onions growing Xerces Society’s Pollinator Outreach Coordinator, I worked as a crop consultant and contract beekeeper, providing pollination services for dozens of crop species across the Midwest (Figure 7.22).

But keeping leafcutter bees wassomething that I never initially intended to do. I knew what they were, and I already had some experience with honey bees and mason bees. But leafcutter bees seemed somehow anachronistic— a reminder of my childhood in North Dakota where abandoned plywood bee shelters dot the Canadian border, collapsing a little more with every prairie winter.

As my pollination work grew, however, I began to see the need for an alternative. Specifically I needed a bee that was active in the summer, that could be deployed on large acres of diverse crops, and that would not abandon the bloom when something better was available down the road. Honey bees met most of those criteria, but not the last one—honey bees often favor distant weeds like sweet clover over marginally appealing crops like onions growing adjacent to their homes.

Leafcutter bees seemed like the logical solution. But where was the information? The few extension type publications I could find were decades old. In the end I had to rely on various Canadian publications geared specifically towards alfalfa producers. From what I had read, the process was simple: set up the nest blocks, release the bees, and let nature take its course.

Nature did take its course, and soon I was battling every type of bee parasite and disease imaginable—things that apparently don’t exist in Canada! Woodpeckers and chipmunks made quick work of my expensive imported Styrofoam nest blocks. And windstorms sent the bee shelters sailing off into the next county. Even my initial bee stock, ordered from Canada, was doomed from the beginning—held up at the border for several weeks by Customs authorities. I think I made every mistake imaginable when starting out.

And yet I persevered.

Over the years I provided pollination services with leafcutter bees on dozens of crop species—everything from rattlesnake master to sunflower. After a lot of experimentation and adaptation of Canadian practices to my local conditions, I began to see more success than failure.

The ongoing plight of honey bees has taught us that our dependence on a single managed pollinator is a risky proposition, one that has the potential for catastrophic results to our fruit, vegetable, forage, and oil crop industries. Viable alternative wild and managed pollinators are essential, and leafcutters can be part of the solution.